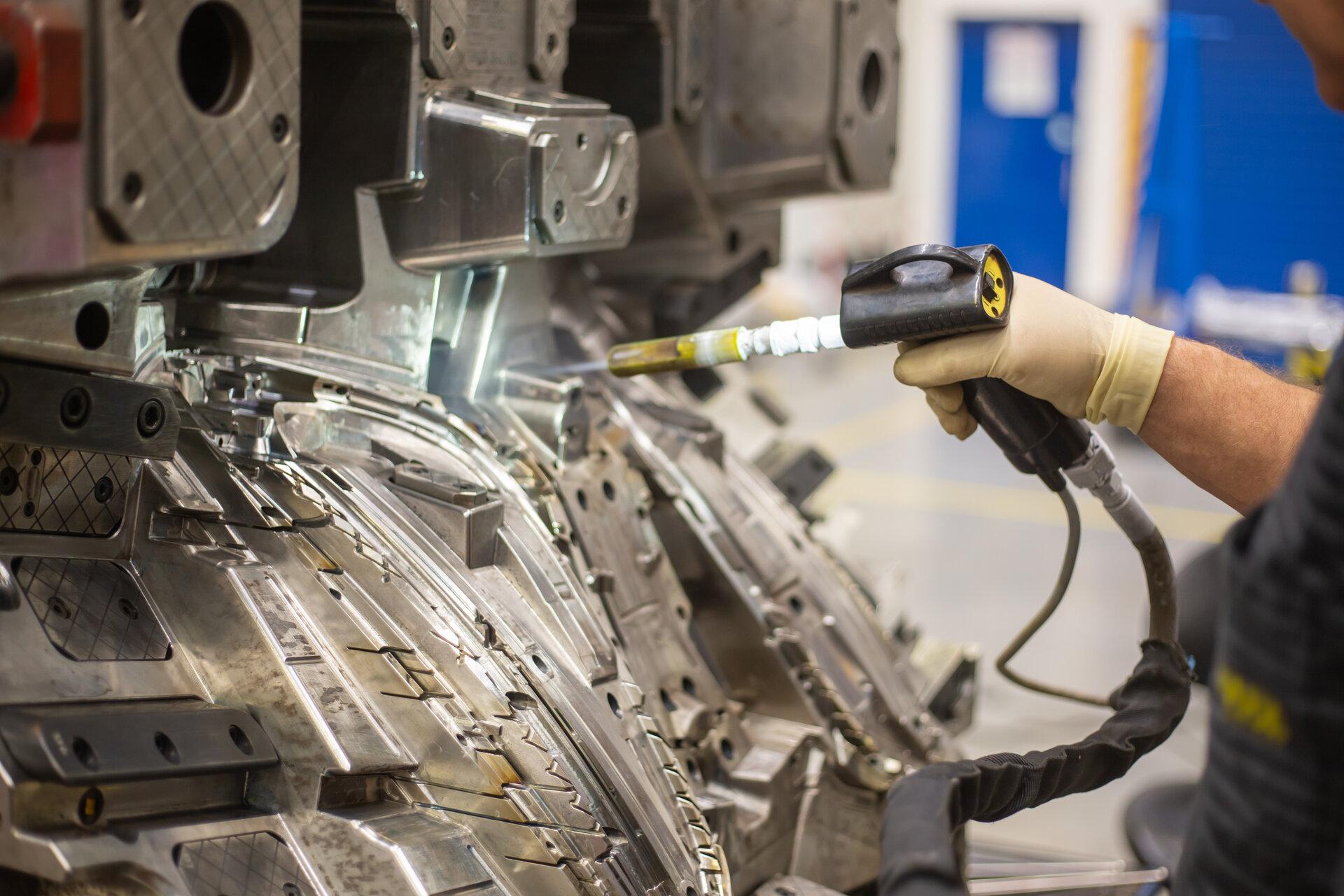

A dry ice machine for cleaning speeds up dry ice pellets with compressed air to clean contaminated surfaces with the help of a jet gun. In principle, this is similar to the steam or sand blasting. However, these are also the only similarities between the usual procedures. If a surface is to be cleaned, chemicals and abrasives can damage it. This works differently for dry ice blasting, because soft dry ice is used in the process. There is no abrasive effect and the surface is not damaged. The dry ice pellets are about 3 millimeters in size and are almost accelerated to the speed of sound with compressed air. During the encounter, mini-explosions are created, which blow up the structure of contamination caused by the cold shock.

What is a Dry Ice Machine for Cleaning?

With the help of the process, it is possible that the undesirable contamination is reliably separated from a surface to be cleaned. After the impact, the dry ice then passes over to the gaseous state and thus evaporates without leaving any residue. As Dry Ice Blasting Equipment, the dry ice blaster is of course very important. Dry ice and compressed air can often be individually controlled. It is therefore possible to react to the degree of pollution and the specific situation of the surface. Only dissolved attachments are then left behind after an application and, if necessary, they must then be disposed of. Effective cleaning is then possible at every tiny angle and cleaning is always residue-free and environmentally friendly. In addition, the cleaning is also time-saving and surface-gentle.

The right Dry Ice Blasting Equipment

If you have the right equipment, you can enjoy a material-friendly cleaning process. The surface is thus not damaged and to which dry ice is antibacterial. The growth of bacteria and moulds is inhibited by dry ice. Since no chemicals are used, the process is environmentally friendly and also biologically harmless. It can be used in the food, cosmetics and pharmaceutical industries. Cleaning is effective and cleaning many objects are possible without time-consuming disassembly. Production residues such as biofilms, resins, oils and paints can be removed without residues. Thanks to the equipment, any steel element, machine or plant can be cleaned effectively and gently. Cleaning with dry ice is an ecological and economical technology. The dry ice blasting equipment is required accordingly in order to allow cleaning. Otherwise, dry ice is also included, which can also be purchased. The service life of the systems can then be extended and everyone saves costs and time during the process. Electronic components, expensive shapes, soft materials or sensitive materials are also no problem.

ource:

Khaligo – stock.adobe.com